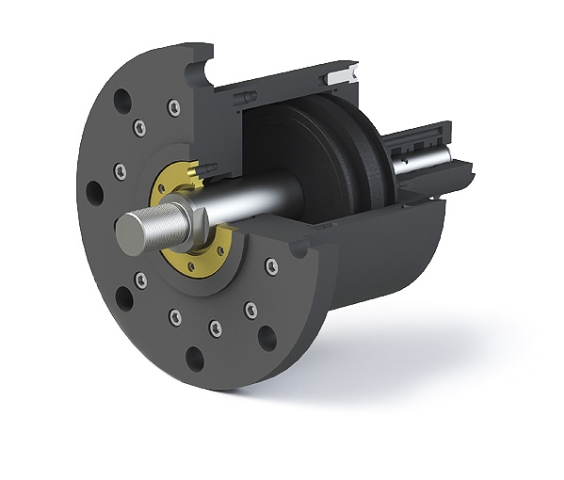

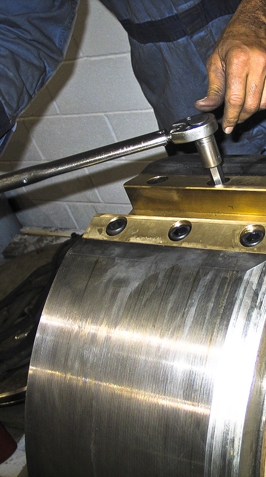

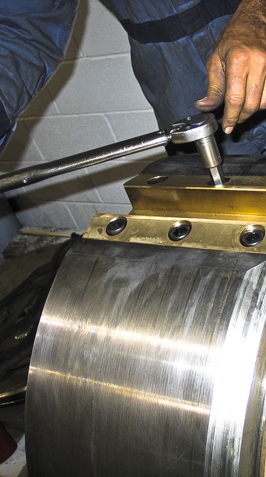

At Anker-Holth, we pride ourselves on our ability to bring damaged cylinders back to their original specifications. We provide repair, modernization and refurbishment services for all types of custom or standard hydraulic and pneumatic cylinders as well as other hydraulic components, regardless of the original manufacturer.

We guarantee prompt, cost effective repairs for maximum uptime. Our repair center and parts warehouse operate under stringent ISO 9001 and Nuclear certification standards. Our experienced technicians measure and evaluate what is necessary to make the cylinders run like new. They work to ensure your equipment will perform optimally in the application for which it was designed and developed.

We have a solid track record in the repair and reconditioning of all makes and models of cylinders, including NFPA / Metric, Mill Type Cylinders, Tie Rod and Welded Construction, Stainless Steel and Coated Process Cylinders., etc. We can handle competitor crossovers. We are equipped to repair custom cylinders of more than 80 inches in diameter and more than 60 feet in length, ranging in bore size from one to 36 inches. We pressure test all pneumatic and hydraulic cylinders before they leave our shop floor to check the integrity of all completed work. We offer timely repairs to rod surface coating, extending the life of the existing rod and minimizing downtime.

Please contact Anker-Holth Repairs at +1 (800) 387-3834