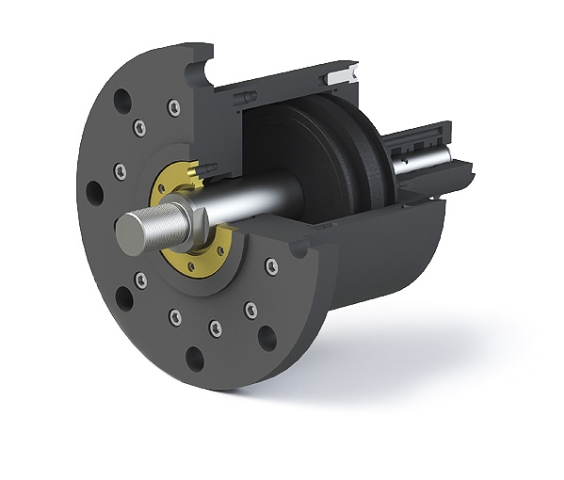

In response to the high production needs of non-ferrous vertical direct-chill casting plants around the world, next- generation Anker-Holth internally guided casting cylinders provide high deflection resistance with a variety of piston rod coatings and seals to ensure smooth, trouble-free casting.

For over 65 years Anker-Holth has supplied cylinders and associated components to aluminum, copper, magnesium and other non-ferrous metal cast houses for smooth, trouble-free casting. Our superior design and custom-fitted components extend the life of Anker-Holth cylinders well beyond expectations. In addition, the extremely close dimensional tolerances of Anker-Holth cylinders ensure casting precision. These tight tolerances prevent excessive rotation to ensure each cast produces straight billets and slabs.

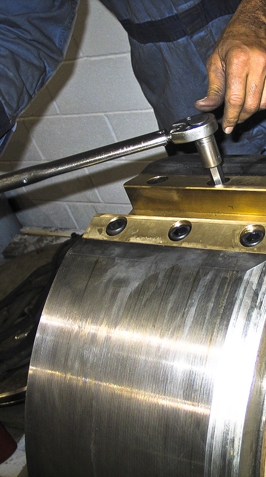

Anker-Holth internally-guided cylinders and large bore, long stroke cylinders for aluminum casting systems are designed to withstand excessive loads. These factors contribute significantly to long service life, efficiency and excellent performance.